Ribbon Processing :

- Ribbons can be processed into tape wound cores of various shapes and dimensions (toroidal, rectangular, oval, etc). Care should be taken in core winding process to minimize fragmentation and achieve the required minimum weight

- Ribbons for medium and large size tape wound cores must be encased with suitable Non-magnetic stainless steel grade after core winding, for protection of core from damage and optimum performance. After heat treatment and testing, the core must be finalized in compatible glue/sealant and top of casing sealed with Insulating material (pre-compressed board, bakelite, fiberglass, etc) as shown

- Ribbons for smaller tape wound cores can also be processed with alternate finish (i.e. fully coated with suitable epoxy and taped in crepe paper or woven fiber cloth, Moulded casings, vacuum impregnation for cut cores, etc ) after heat treatment. However its performance will be lower than Stainless Steel encased cores due to surface stresses endured by the core in coating process.

- Nanocrystalline being a soft magnetic material, absolute care should be taken while handling the bare and annealed core. Any excess external pressure, shocks, vibrations etc. will lead to deterioration in core performance.

- Precautionary measures must be taken in the finalization process to ensure that no part of the annealed core is directly exposed to the atmosphere or come in contact with wetness, moisture, dry heat, sunlight, etc.

Heat Treatment :

- Cores made from these Ribbons need to be well-annealed in suitable annealing furnace with appropriate time-temperature sequence.

- Various types of annealing are possible depending on the expected ribbon performance.

- Material handling and furnace operation are critical to achieving optimum output of cores.

Packaging Solutions :

- Ribbons are Wound as Reels having Average OD:190-200mm and wound on a plastic bobbin having Average ID:20mm Last Reel of Ribbon Cycle/Batch may have smaller OD wound due to it being wound at the end of cycle

- Max Weight of Ribbon Reel: 10Kgs

- Ribbon Reels of same cycle width are stacked together and placed inside PP/PE bags having thickness more than 50microns

- Ribbon Stack is placed insider Corrugated Cardboard box with Protective Foam at all Corners to prevent from damage.

- Sticker showing Production Cycle No with Date of Production is affixed on each box.

- Packing List and Mill Test Certificate is provided inside the box and copy attached with Sale Invoice

Envinronmental Conditions & Storage/Handling Instructions

- Nanocrystalline is an ROHS-2 compliant Non-Hazardous Material

- Item must be stored in a Cool and Well-Ventilated Area

- Keep Away from Direct Sunlight or Exposure to Moisture

- Item must be stored in its Original Packaging only

- Storage Temperature: 20°C~45°C

- Humidity: Average < 95%

- Delicate/Fragile Material. To be Handled with utmost care.

- Do not mishandle/drop the Material. It can result in Fragmentation and permanent damage

- When taking the material outside its original packaging and/or at any time during its use, the reels may become loose and ribbons may uncoil making side surface uneven. Therefore, always use a support plate at both, top and bottom of the reels as shown before use to ensure smooth ribbon uncoiling and core winding.

- Like most Fe-based materials, Nanocrystalline tends to oxidise after exposure to atmosphere. Therefore, after opening the product from its packaging, it is to be used as soon as possible to avoid deterioration from exposure to climatic conditions.

Safety

- Nanocrystalline Ribbon is an ultra-fine material with sharp edges. Use only cut-resistant hand-gloves of suitable material before handling the ribbons.

- Risk of fragmentation exists due to brittleness in the ribbon. Therefore, no excess pressure should be applied while handling the ribbon to avoid fragmentation.

- Wear Safety Goggles at all times while handling the ribbon as flying fragments can enter and damage the unprotected eye.

- Wearing of face mask is mandatory during material handling for one’s own safety.

Quality Assurance

- Due to the Nature of Mass Ribbons production, Quality Certificates for Nanocrystalline Ribbons are provided as per Inspections done on Random Sampling basis only.

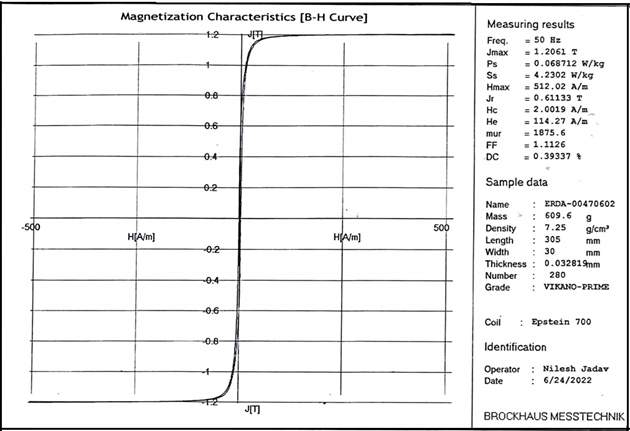

- For Core design using these ribbons, kindly refer the attached Annexure-A on typical Magnetisation Curves.

- In the event of any non-conformance, we guarantee to jointly discuss and help find a solution to the problem amicably.

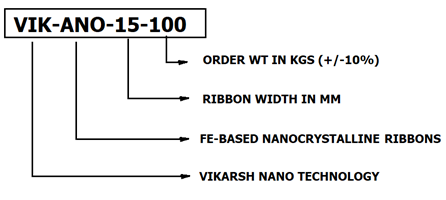

Ordering Information

| Minimum Order Quantity | 15 kgs |

|---|---|

| Minimum Ribbon Width TH | 10 mm |

| Maximum Ribbon Width TH | 40 mm |