Nano Cut Core & Blocks

Nano Cut Core are Wound, Vacuum Impregnated, and CNC Wire Cut Cores made from Nano crystalline and Amorphous Ribbons. Fully customized to user’s requirements.Can be supplied as 2-part (i.e.fully cut) core and 1-part (i.e. single-gap core) used for high frequency applications in Medical Segment and Power Electronics.

Cut Core Applications :

- Used for Manufacturing X-Ray Machine Generator Transformers

- Used for High Saturation Chokes and Inductors

- Other Special Applications

Blocks are Vacuum Impregnated blocks and special profile cut blocks made from Nanocrystalline ribbons and Amorphous ribbons having superior performance at High Frequency Applications

Blocks Applications :

- Used in EV Chargers

- Used as Profile-Cut Blocks for special Motor Stators

- Used for Different types of Inductors.

- Used Special Applications in defence and medical sector.

Features :

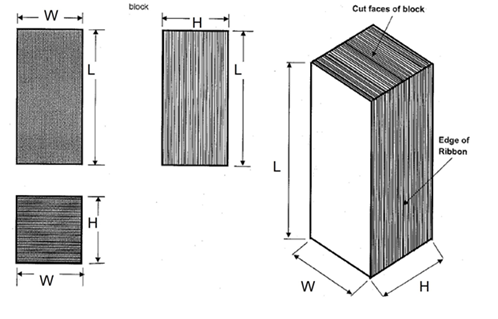

- Rectangular Form.

- Easy to Mount Coils.

- Wide Working Temperature Range (-40°C to 130°C).

- With Air Gap. Excellent anti-bias current ability.

- High Saturation Flux Density.

- Low Coercivity.

- Low Power Loss.

- Can be customized into various Shapes and Forms.

Country Of Origin :

- India

Material Specifications :

| Material | Amorphous or Nanocrystalline |

|---|---|

| Initial Magnetic Permeability | µi > 80,000 or 8,000 |

| Maximum Magnetic Permeability | µm > 600,000 |

| Density | 7.25gms/cm3 |

| Resistivity (μ.Ω.cm) | 130 |

| Coercivity (A/m) | < 4 |

| Ribbon Thickness | 35µm (+/-5µm) |

| Saturation Induction | From 1.2 upto 1.6Tesla at 50Hz |

| Lamination Factor | 0.75 ~ 0.80 |

| Typical Core Loss | 0.1 W/kg at 50Hz |

Physical Properties :

- Appearance: Generally Smooth and Glossy Surface

- Available Widths: 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm

- Width Tolerances: (10-30)mm: +/-0.5mm (30-45)mm: +/- 0.6mm

- Length Tolerances: (+/-1.0mm) upto 100mm, (+/-1.5mm) upto 200mm (+/-2.0mm) upto 300mm

Mounting and Construction :

- Suitable for both Open and Closed Loop Assembly.

- Block cores can be positioned both, vertically and horizontally Care Should be taken to reduce air gap at mating edges.

- Suitable clamps can be used to hold core assembly in position Clamping structures must be insulated from Block Cores.

- Suitable for copper winding. However, appropriate foam cushion and insulating material must be used depending on operating voltage of the application.

- Not suitable for direct immersion in liquid or cast resin epoxy as product is not encapsulated.

Quality Assurance

Due to the Special nature (i.e. shapes and Geometries) and enhanced processes involved in the fabrication of block cores, guaranteed parameters will be as per actual values achieved in feasibility trials taken.

Ordering Information

| Minimum Order Quantity | 50 kgs |

|---|---|

| Minimum Ribbon Width TH | 10 mm |

| Maximum Ribbon Width TH | 40 mm |

| Material | VIKANO® VIKAMO® |

Envinronmental Conditions & Storage/Handling Instructions

- Nanocrystalline is an ROHS-2 compliant Non-Hazardous Material

- Item must be stored in a Cool and Well-Ventilated Area

- Keep Away from Direct Sunlight or Exposure to Moisture

- Item must be stored in its Original Packaging only

- Storage Temperature: 20°C~45°C

- Humidity: Average < 95%

- Delicate/Fragile Material. To be Handled with utmost care.

- Do not mishandle/drop the Material. It can result in Fragmentation and permanent damage When taking the material outside its original packaging and/or at any time during its use, the reels may become loose and ribbons may uncoil making side surface uneven. Therefore, always use a support plate at both, top and bottom of the reels as shown before use to ensure smooth ribbon uncoiling and core winding.

- Like most Fe-based materials, Nanocrystalline tends to oxidise after exposure to atmosphere. Therefore, after opening the product from its packaging, it is to be used as soon as possible to avoid deterioration from exposure to climatic conditions.

Safety

- Nanocrystalline is an ultra-fine material with sharp edges. Use only cut-resistant hand-gloves of suitable material before handling the ribbons.

- Risk of fragmentation exists due to brittleness in the ribbon. Therefore, no excess pressure should be applied while handling the ribbon to avoid fragmentation.

- Wear Safety Goggles at all times while handling the ribbon as flying fragments can enter and damage the unprotected eye.

- Wearing of face mask is mandatory during material handling for one’s own safety.

The following Notes applies to all items and components mentioned in this publication

- Some sections of this publication may contain information regarding the possible areas of application of our products and its suitability for use in them. This information is based on our knowledge of this product and its requirements given by customers using these products in similar areas of application and the feedback provided by them after use. Nevertheless we explicitly state that such statements are only a guide and cannot be regarded as legally binding statements on suitability of the product for a specific application.

- Misoperation or failure of the product before end of its service life cannot be ruled out even if operated as specified. For applications requiring a high level of operational safety especially in areas where risk of malfunction can result in loss of life, health, of bodily injury, it is expected that the customer take appropriate actions and measures (like installation of protective equipment, safe working protocol, etc) to ensure that no bodily injury or damage of any kind in incurred in case of misoperation or failure of the product.

- Product-specific warnings, caution notes, etc are to be well observed before and during use of the product.

- Being an Organisation continuously engaged in Design & Development, we continuously strive to improve the quality and operational performance of our products in the field. Consequently, it is likely that the product described in this publication is bound to change/improve from time to time. The same is also true for specifications provided with this product. It is therefore expected that the customer check for changes in the product specifications and its areas of application at the time of order placement for the same.

- It is equally likely that certain products may be discontinued from production and/or new products introduced in its place. These may be dependent on a number of factors like supply & demand, competitiveness, efficiency, etc. We therefore cannot guarantee that older versions of our product will continue to be available and reserve the right to discontinue production as and when the need may arise. We however clarify that this does not apply to customers with whom we are having individual agreements with for supply of customer-specific products.

- Unless mentioned otherwise, all Orders we governed by the Terms and Conditions of Supply provided in the Budgetary Offer/Commercial Quotation for the said product.

- Any Disputes arising from the Sale of the product will be subject to the decision of the courts in Pune Jurisdiction alone.

- Our Manufacturing facility is ISO-9001, ISO-14001 & ISO-45001 Certified. These certifications confirm our compliance with the requirements stipulated in the Quality Management System and Environment, Health and Safety Standards. As far as customer-specific requirements are concerned, Vikarsh Nano Technology will continue to honour its commitment of respecting individual agreements in true spirit. Only mutually agreed requirements will be implemented in our systems.

- The Trade Name: Vikano® is a product name identified by Vikash Nano Technology for Fe-based Nanocrystalline Ribbons and for which trademark registration is pending.

.jpeg)